News

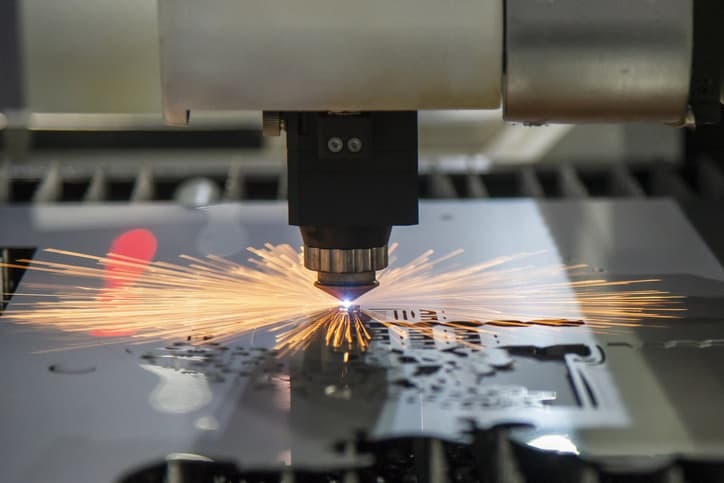

Exploring the Remarkable Precision of the Laser Cutting Process at DINOZOZO

Are you intrigued by the magical precision of custom laser-cut metal signs? Have you ever wondered how these intricate designs come to life with immaculate detail and clean edges? Join DINOZOZO on a fascinating journey as we delve into the mesmerizing world of laser cutting and unveil the secrets behind this intricate process.

The Basics of Laser Cutting

Laser cutting is a sophisticated manufacturing technique that employs a high-powered laser beam to precisely cut or engrave various materials, including metals. The process is highly sought after for creating intricate, custom designs with incredible precision. Here’s how it works:

The Laser Source

The process begins with a high-energy laser source, which can be a CO2 or fiber laser. The choice of laser depends on the material being cut. CO2 lasers are ideal for non-metallic materials, while fiber lasers are perfect for metals.

Material Preparation

Before the laser can work its magic, the metal sheet or plate must be securely fixed in place on the cutting bed. Proper positioning ensures that the laser cuts exactly where it’s supposed to.

Computer-Aided Design (CAD)

The heart of the operation lies in the design. Skilled designers use Computer-Aided Design (CAD) software to create intricate patterns and shapes. This digital file contains instructions for the laser cutter, dictating where and how to cut.

The Precision Cut

With the design file loaded, the laser cutter springs into action. The high-energy laser beam precisely follows the pattern outlined in the CAD file, cutting through the metal with remarkable accuracy. The intensity of the laser vaporizes or melts the material, leaving behind a clean, precise cut. The best part? It’s an extremely fast process.

Minimal Heat-Affected Zone

One of the benefits of laser cutting is its ability to create fine, detailed cuts with minimal heat transfer. This is due to the small, concentrated laser beam. The result is a clean and sharp edge that doesn’t require additional finishing.

Clean Edges and Intricate Detail

The precision of laser cutting is evident in the quality of the finished product. The edges of the cut material are smooth and clean, requiring little to no post-processing. This is why laser cutting is the preferred method for crafting custom metal signs and intricate designs.

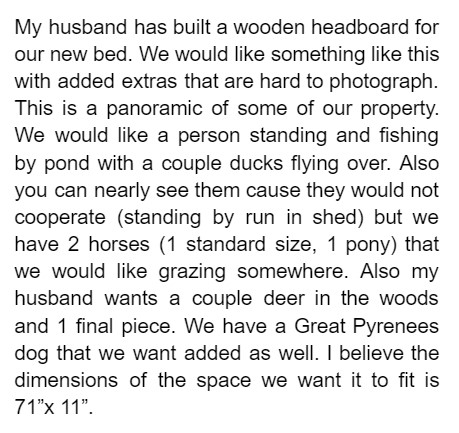

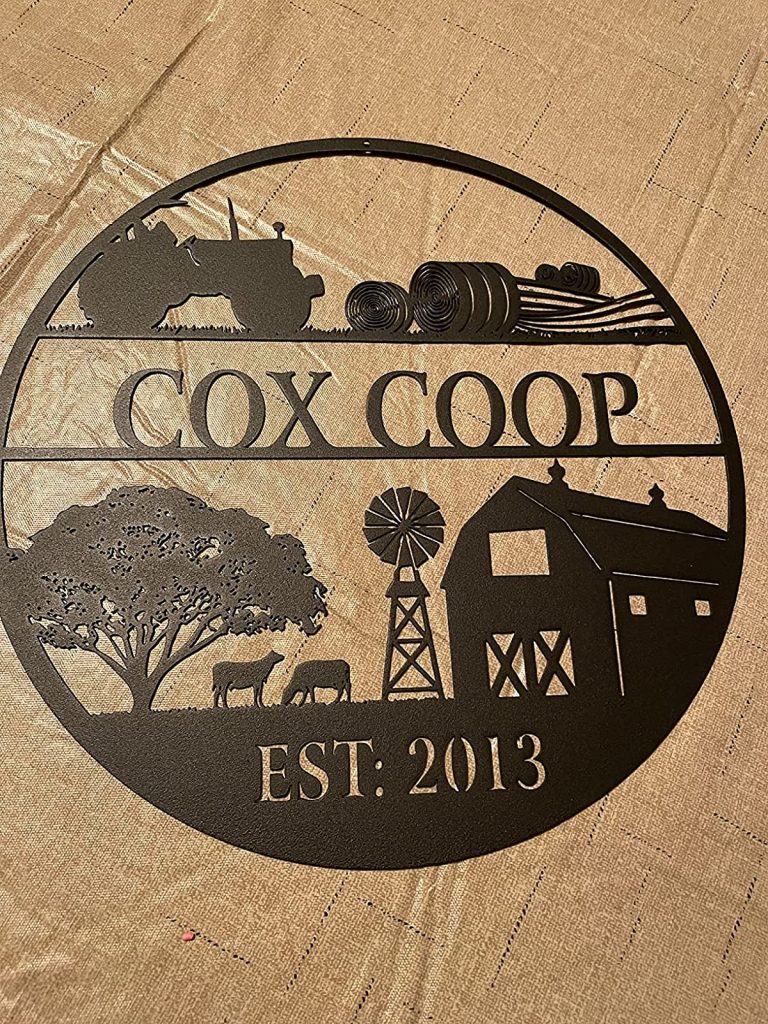

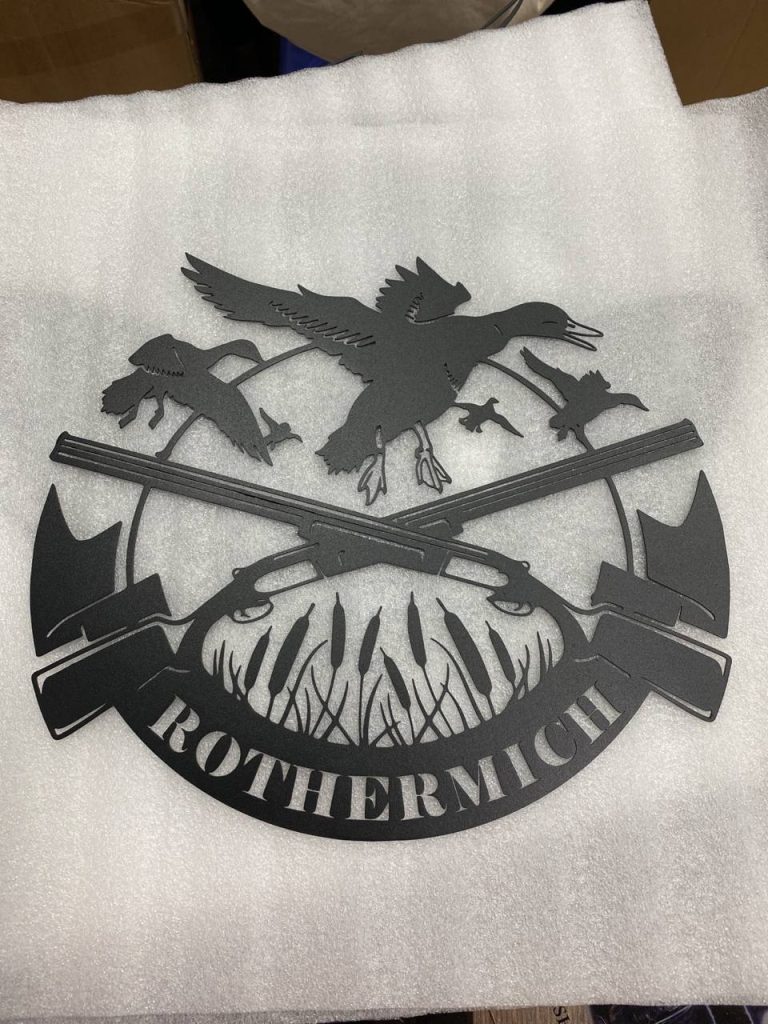

Customization Galore

Because laser cutting is guided by digital files, it allows for an incredible level of customization. Your design can be as unique as your imagination, making it the perfect choice for personalized metal signs.

Laser Cutting at DINOZOZO

At DINOZOZO, we take pride in our mastery of the laser cutting process. Our team of skilled artisans combines state-of-the-art laser cutting technology with a passion for craftsmanship to create stunning, custom metal signs. Whether it’s a personalized wedding gift, a business logo, or a decorative piece for your home, our laser-cut metal signs are a testament to the artistry of precision.

Are you ready to turn your creative vision into reality? Explore the endless possibilities of custom metal signs with DINOZOZO and experience the magic of laser cutting firsthand. Contact us today to embark on your next custom sign project, and let our team of experts bring your design to life with unparalleled precision and artistry.